Introduction

The belt in most Dymo DiscPainters has returned to the dinosaurs and turned to tar, rendering the machine entirely unusable - even if you were already aware that you could use a Lexmark #1 color print cartridge instead of the long-obsolete Dymo cartridge (simply trim off a small plastic tab).

The symptom of a broken belt is a turntable that spins far too freely, and for far too long when flung with a finger. When flung with maximum gusto, the turntable should stop spinning within about 1 second if the belt is good (and you can hear the motor whirring inside when you do). If the belt is broken, it'll spin near-endlessly. When you try to print, you'll likely get a printer error of some kind, as it's not tracking turntable movement when it's expected.

The procedure to replace the belt is a bit invasive and fiddly, but if you get it right, your DiscPainter can continue printing in 2024 and beyond!

-

-

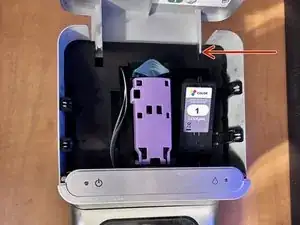

Press inward on the hinge (as arrow, on the thinner side) to disconnect this side of the lid.

-

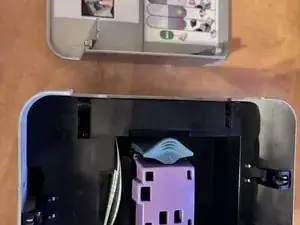

The opposite side of the lid will now be free to fully remove.

-

-

-

Remove 6 Philips #2 screws that secure the upper chassis to the lower chassis.

-

The upper and lower chassis should simply lift apart.

-

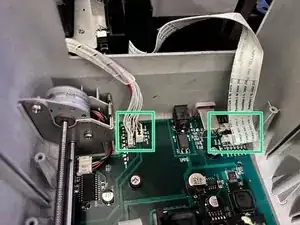

Disconnect the two printhead ribbon cables (careful to keep them in that layered order when reassembling!) and the sensor connectors, which simply lift out.

-

-

-

Pop out the C-clip in the rear of the machine, attaching the rail to the motor mount.

-

Pop out the C-clip in the front of the machine on the opposite rail, attaching the rail to the chassis.

-

Once the C-clips are removed, simply slide each rail in the direction that was freed by the C-clip, and it should dislodge the opposite end, which allows you to pivot the rod and completely remove the rod.

-

Tilt the print bed mechanism on its side, revealing the ribbon connector to the main board.

-

To unlock the ribbon connector on the board, slide the locking tabs towards the back, parallel to the board, at the same time. They should move approximately 1-2mm, and the ribbon cable should then move freely within the socket, requiring no force to remove it, as it is a zero insertion force (ZIF) connection.

-

-

-

Remove 6 Philips #2 screws that secure the lower print bed to the upper cover.

-

The turntable belt can now be accessed for cleanup and replacement.

-

To reassemble your device, follow these instructions in reverse order.