Short Question

Is there a common way to handle very large anomalies (order of magnitude) within an otherwise uniform control region?

Background

I am working on a control algorithm that drives a motor across a generally uniform control region. With no / minimal loading the PID control works great (fast response, little to no overshoot). The issue I'm running into is there will usually be at least one high load location. The position is determined by the user during installation, so there is no reasonable way for me to know when / where to expect it.

When I tune the PID to handle the high load location, it causes large over shoots on the non-loaded areas (which I fully expected). While it is OK to overshoot mid travel, there are no mechanical hard stops on the enclosure. The lack of hardstops means that any significant overshoot can / does cause the control arm to be disconnected from the motor (yielding a dead unit).

Things I'm Prototyping

- Nested PIDs (very agressive when far away from target, conservative when close by)

- Fixed gain when far away, PID when close

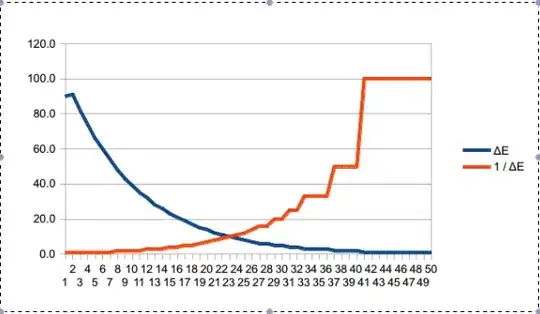

- Conservative PID (works with no load) + an external control that looks for the PID to stall and apply additional energy until either: the target is achieved or rapid rate of change is detected (ie leaving the high load area)

Hardware Limitations

- Full travel defined

- Hardstops cannot be added (at this point in time)

Update

My answer does not indicate that this is best solution. It's just my current solution that I thought I would share.