| |

| Names | |

|---|---|

| Preferred IUPAC name

5,5-Dimethyl-3,7-dioxa-1,9(2)-bis(oxirana)-4,6(2,4)-dibenzenanonaphane | |

| Other names

Diglycidyl ether of bisphenol A; 2,2-Bis(4-glycidyloxyphenyl)propane; Epoxide A | |

| Identifiers | |

3D model (JSmol) |

|

| Abbreviations | BADGE; DGEBA |

| ChemSpider | |

| ECHA InfoCard | 100.015.294 |

| EC Number |

|

| KEGG | |

| MeSH | C019273 |

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C21H24O4 | |

| Molar mass | 340.419 g·mol−1 |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

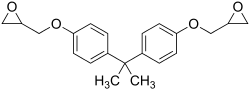

Bisphenol A diglycidyl ether (commonly abbreviated BADGE or DGEBA) is an organic compound and is a liquid epoxy resin.[1][2][3][4][5] The compound is a colorless viscous liquid (commercial samples can appear pale straw-coloured).[6][7] It is a key component of many epoxy resin formulations. Addition of further Bisphenol A and a catalyst and heat can produce Bisphenol A glycidyl ether epoxy resins of higher molecular weight that are solid.[8]

Preparation and reactions

It is prepared by O-alkylation of bisphenol A with epichlorohydrin. This reaction mainly affords bisphenol A diglycidyl ether, as well as some oligomer. The degree of polymerization may be as low as 0.1.[9] The epoxide content of such epoxy resins is of interest. This parameter is commonly expressed as the epoxide number, which is the number of epoxide equivalents in 1 kg of resin (Eq./kg), or as the equivalent weight, which is the weight in grams of resin containing 1 mole equivalent of epoxide (g/mol). Since unsymmetrical epoxides are chiral, the bis epoxide consists of three stereoisomers, although these are not separated.

Bisphenol A diglycidyl ether slowly hydrolyzes to 2,2-bis[4(2,3-dihydroxypropoxy)phenyl)propane (bis-HPPP).

Similarly, DGEBA reacts with acrylic acid to give vinyl ester resins. The reaction results in opening of the epoxide ring, generating unsaturated esters at each terminus of the molecule. Such materials are often diluted with styrene and converted to resin.

Epoxy resins are thermosetting polymers, which are crosslinked using hardeners (curing agents). The most common curing agents for epoxy resins are polyamines, aminoamides, and phenolic compounds.[10]

Safety

BADGE is highly reactive and forms a number of species upon exposure to water or HCl and many of these compounds (including BADGE) are suspected endocrine disruptors[11] Hydrolysis of the ether bonds liberates bisphenol A, which is also strongly suspected of being an endocrine disruptor.[12][13] From the 1990s onward, concern has been raised over the use of BADGE-based epoxy resins in the lining of some cans for foodstuffs, with the chemical being found to leach into foods.[12][14] Bisphenol A Diglycidyl ether-based epoxy coatings are extensively used for coating the inside of cans which come into contact with food and are thus food contact materials. The materials and analogues and conjugates have been extensively tested for and analytical methods developed.[15][16]

See also

- Bisphenol AF (BPAF)

- Bisphenol S (BPS)

- EPI-001

References

- ↑ Ellis, Bryan (1993). Chemistry and Technology of Epoxy Resins. Dordrecht: Springer Netherlands. ISBN 978-94-011-2932-9. OCLC 851368739.

- ↑ "Bisphenol A Liquid Epoxy Resins | Business & Products". DIC Corporation. Retrieved 2023-01-11.

- ↑ "Epoxy: A Complete Guide". Copps Industries. Retrieved 2023-01-11.

- ↑ PubChem. "Bisphenol A diglycidyl ether". pubchem.ncbi.nlm.nih.gov. Retrieved 2023-01-11.

- ↑ "2,2-Bis(4-glycidyloxyphenyl)propane 1675-54-3 | TCI AMERICA". www.tcichemicals.com. Retrieved 2023-01-11.

- ↑ Hofer, Arnold; Schneider, Hildegard, and Siegenthaler, Nikolaus (1996) "Epoxy resin mixtures containing advancement catalysts", U.S. Patent 5,521,261.

- ↑ Pham, Ha Q.; Marks, Maurice J. (2012). "Epoxy Resins". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a09_547.pub2. ISBN 978-3527306732.

- ↑ Ashcroft, W. R. (1993), Ellis, Bryan (ed.), "Curing agents for epoxy resins", Chemistry and Technology of Epoxy Resins, Dordrecht: Springer Netherlands, pp. 37–71, doi:10.1007/978-94-011-2932-9_2, ISBN 978-94-010-5302-0, retrieved 2023-01-11

- ↑ Mark, Herman (16 October 2013). "Epoxy Resins". Encyclopedia of Polymer Science and Technology. ISBN 9780470073698.

- ↑ Forrest, M.J.: Coatings and Inks for Food Contact Materials, in RAPRA review reports, vol. 16, no. 6 (2005), p.8

- ↑ Wang, Dongqi; Zhao, Haoduo; Fei, Xunchang; Synder, Shane Allen; Fang, Mingliang; Liu, Min (October 2021). "A comprehensive review on the analytical method, occurrence, transformation and toxicity of a reactive pollutant: BADGE". Environment International. 155: 106701. doi:10.1016/j.envint.2021.106701. hdl:10356/161451. PMID 34146765.

- 1 2 Walfried Rauter, Gerald Dickinger, Rudolf Zihlarz and Josef Lintschinger, "Determination of Bisphenol A diglycidyl ether (BADGE) and its hydrolysis products in canned oily foods from the Austrian market", Z. Lebensm. Unters. Forsch. A 208 (1999) 208–211

- ↑ "Leitlinie zur hygienischen Beurteilung von organischen Beschichtungen im Kontakt mit Trinkwasser (Beschichtungsleitlinie)" [Guideline for public health evaluation of organic chemical coatings in contact with drinking water (coating guideline)] (PDF). www.umweltbundesamt.de (in German). 16 March 2016. Archived from the original (PDF) on 9 January 2017. Retrieved 6 October 2019.

- ↑ Berdasco, Nancy Anne M.; Waechter, John M. (2012-08-17), Bingham, Eula; Cohrssen, Barbara; Powell, Charles H. (eds.), "Epoxy Compounds: Aromatic Diglycidyl Ethers, Polyglycidyl Ethers, Glycidyl Esters, and Miscellaneous Epoxy Compounds", Patty's Toxicology, Hoboken, NJ, USA: John Wiley & Sons, Inc., pp. 491–528, doi:10.1002/0471435139.tox083.pub2, ISBN 978-0-471-12547-1, retrieved 2022-07-28

- ↑ Lestido-Cardama, Antía; Sendón, Raquel; Rodríguez Bernaldo de Quirós, Ana (2022-11-01). "Tentative identification of BADGE derivatives in epoxy type coatings in a model sample: a beverage can". Journal of Coatings Technology and Research. 19 (6): 1893–1900. doi:10.1007/s11998-022-00662-6. ISSN 1935-3804. S2CID 251912604.

- ↑ Beszterda, Monika; Tądrowska, Magdalena; Frański, Rafał (2022-11-01). "Multi-detection method for the fast screening of bisphenol A diglycidyl ether conjugates in the can-coating material". Journal of Coatings Technology and Research. 19 (6): 1901–1907. doi:10.1007/s11998-022-00668-0. ISSN 1935-3804. S2CID 252213795.