OK lets start with the absolute basics.

support shape

You can use any shape to meet the specifics of used printing technology. The easiest to generate within STL is 3 side prism like shape which contains 2 triangular bases (top and bottom) and 3 sides all of which have 2 triangles. So 8 triangles total.

This shape will start at some base plane (Z=0) and will go up until it hits the mesh. However to make this work the support must have a small gap between mesh and itself where we will add our weakened joint structure with mesh latter on.

support pattern

there are a lot of options here so I chose the simplest (not foul proof however) and that is to place the supports in a uniform grid with constant distance grid between the supports.

so simply cast a ray from each grid position on the base plane in up direction and check for intersection with mesh. If found place the support at that position with height just gap below the intersection point.

Joints

The idea is to join fan of very thin supports in cone like shape connecting & covering the supported surface above main support prism with less than 45 deg angle (so the gap should be big enough to cover grid distance in such manner).

The main problem here is that we must subdivide the triangles we are connecting to so we meet the STL mesh properties. To solve the connection problem (avoid holes or breaking connection requirements of the STL) we can use different solid for supports and different for our mesh. That will also allow us to touch surfaces without re-triangulating them making this a lot easier task.

For simplicity I chose tetrahedron shape which is simple to construct from triangles and also present weakness at the mesh/support joint.

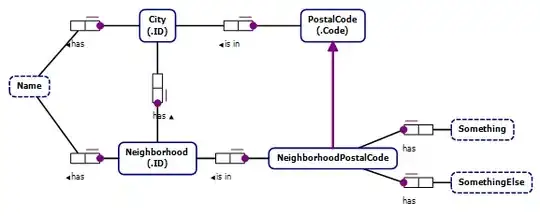

So let us take some test STL mesh and place it above our base plane:

and place our main supports:

and also the joints:

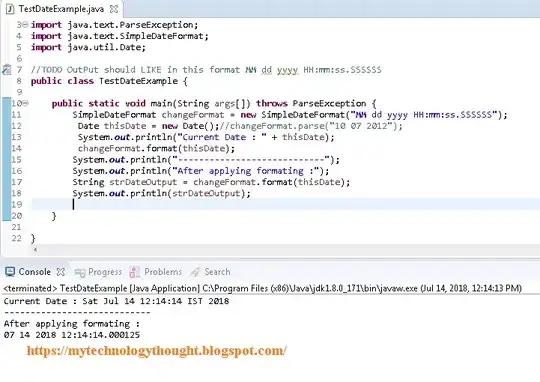

Here VCL/C++ code for this STL3D.h:

//---------------------------------------------------------------------------

//--- simple STL 3D mesh ----------------------------------------------------

//---------------------------------------------------------------------------

#ifndef _STL3D_h

#define _STL3D_h

//---------------------------------------------------------------------------

#ifdef ComctrlsHPP

TProgressBar *progress=NULL; // loading progress bar for realy big STL files

#endif

void _progress_init(int n);

void _progress (int ix);

void _progress_done();

//---------------------------------------------------------------------------

class STL3D // STL 3D mesh

{

public:

double center[3],size[3],rmax; // bbox center,half sizes, max(size[])

struct _fac

{

float p[3][3]; // triangle vertexes CCW order

float n[3]; // triangle unit normal pointing out

WORD attr;

_fac() {}

_fac(_fac& a) { *this=a; }

~_fac() {}

_fac* operator = (const _fac *a) { *this=*a; return this; }

//_fac* operator = (const _fac &a) { ...copy... return this; }

void compute() // compute normal

{

float a[3],b[3];

vectorf_sub(a,p[1],p[0]);

vectorf_sub(b,p[2],p[1]);

vectorf_mul(n,a,b);

vectorf_one(n,n);

}

double intersect_ray(double *pos,double *dir) // return -1 or distance to triangle and unit ray intersection

{

double p0[3],p1[3],p2[3]; // input triangle vertexes

double e1[3],e2[3],pp[3],qq[3],rr[3]; // dir must be unit vector !!!

double t,u,v,det,idet;

// get points

vector_ld(p0,p[0][0],p[0][1],p[0][2]);

vector_ld(p1,p[1][0],p[1][1],p[1][2]);

vector_ld(p2,p[2][0],p[2][1],p[2][2]);

//compute ray triangle intersection

vector_sub(e1,p1,p0);

vector_sub(e2,p2,p0);

// Calculate planes normal vector

vector_mul(pp,dir,e2);

det=vector_mul(e1,pp);

// Ray is parallel to plane

if (fabs(det)<1e-8) return -1.0;

idet=1.0/det;

vector_sub(rr,pos,p0);

u=vector_mul(rr,pp)*idet;

if ((u<0.0)||(u>1.0)) return -1.0;

vector_mul(qq,rr,e1);

v=vector_mul(dir,qq)*idet;

if ((v<0.0)||(u+v>1.0)) return -1.0;

// distance

t=vector_mul(e2,qq)*idet;

if (t<0.0) t=-1.0;

return t;

}

};

List<_fac> fac; // faces

STL3D() { reset(); }

STL3D(STL3D& a) { *this=a; }

~STL3D() {}

STL3D* operator = (const STL3D *a) { *this=*a; return this; }

//STL3D* operator = (const STL3D &a) { ...copy... return this; }

void reset(){ fac.num=0; compute(); } // clear STL

void draw(); // render STL mesh (OpenGL)

void draw_normals(float size); // render STL normals (OpenGL)

void compute(); // compute bbox

void compute_normals(); // recompute normals from points

void supports(reper &obj); // compute supports with obj placement above base plane z=0

void load(AnsiString name);

void save(AnsiString name);

};

//---------------------------------------------------------------------------

void STL3D::draw()

{

_fac *f; int i,j; BYTE r,g,b;

glBegin(GL_TRIANGLES);

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

glNormal3fv(f->n);

if (f->attr<32768)

{

r= f->attr &31; r<<=3;

g=(f->attr>> 5)&31; g<<=3;

b=(f->attr>>10)&31; b<<=3;

glColor3ub(r,g,b);

}

for (j=0;j<3;j++) glVertex3fv(f->p[j]);

}

glEnd();

}

//---------------------------------------------------------------------------

void STL3D::draw_normals(float size)

{

_fac *f;

int i; float a[3],b[3];

glBegin(GL_LINES);

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

vectorf_add(a,f->p[0],f->p[1]);

vectorf_add(a,a ,f->p[2]);

vectorf_mul(a,a,1.0/3.0);

vectorf_mul(b,f->n,size); glVertex3fv(a);

vectorf_add(b,b,a); glVertex3fv(b);

}

glEnd();

}

//---------------------------------------------------------------------------

void STL3D::compute()

{

_fac *f;

int i,j,k;

double p0[3],p1[3];

vector_ld(center,0.0,0.0,0.0);

vector_ld(size,0.0,0.0,0.0);

rmax=0.0;

if (fac.num==0) return;

// bbox

for (k=0;k<3;k++) p0[k]=fac.dat[0].p[0][k];

for (k=0;k<3;k++) p1[k]=fac.dat[0].p[0][k];

for (f=fac.dat,i=0;i<fac.num;i++,f++)

for (j=0;j<3;j++)

for (k=0;k<3;k++)

{

if (p0[k]>f->p[j][k]) p0[k]=f->p[j][k];

if (p1[k]<f->p[j][k]) p1[k]=f->p[j][k];

}

vector_add(center,p0,p1); vector_mul(center,center,0.5);

vector_sub(size ,p1,p0); vector_mul(size ,size ,0.5);

rmax=size[0];

if (rmax<size[1]) rmax=size[1];

if (rmax<size[2]) rmax=size[2];

// attr repair

for (f=fac.dat,i=0;i<fac.num;i++,f++)

if (f->attr==0) f->attr=32768;

}

//---------------------------------------------------------------------------

void STL3D::compute_normals()

{

_fac *f; int i;

for (f=fac.dat,i=0;i<fac.num;i++,f++) f->compute();

}

//---------------------------------------------------------------------------

void STL3D::supports(reper &obj)

{

_fac *f,ff;

int i,j,k;

double p[3],dp[3],x0,y0,h0,x1,y1,x2,y2,h1,t;

// some config values first

const WORD attr0=31<<10; // support attr should be different than joint

const WORD attr1=31<<5; // joint attr should be different than mesh,support

const double grid0=8.0; // distance between supports

const double grid1=2.0; // distance between joints

const double gap=grid0/tan(45.0*deg);// distance between main support and mesh (joint size)

const double ha=1.0; // main support side size

// do not mess with these

const double hx= ha*cos(60.0*deg); // half size of main support in x

const double hy=0.5*ha*sin(60.0*deg); // half size of main support in y

const double grid2=0.4*hy; // distance between joints bases

const double ga=2.0*grid2*grid1/grid0; // main support side size

const double gx=hx*grid2/grid0; // half size of joint support in x

const double gy=hy*grid2/grid0; // half size of joint support in y

// apply placement obj (may lose some accuracy) not needed if matrices are not used

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

for (j=0;j<3;j++)

{

for (k=0;k<3;k++) p[k]=f->p[j][k]; // float->double

obj.l2g(p,p);

for (k=0;k<3;k++) f->p[j][k]=p[k]; // double->float

}

for (k=0;k<3;k++) p[k]=f->n[k]; // float->double

obj.l2g_dir(p,p);

for (k=0;k<3;k++) f->n[k]=p[k]; // double->float

} compute();

// create supports

for (x0=center[0]-size[0]+(0.5*grid0);x0<=center[0]+size[0]-(0.5*grid0);x0+=grid0)

for (y0=center[1]-size[1]+(0.5*grid0);y0<=center[1]+size[1]-(0.5*grid0);y0+=grid0)

{

// cast ray x0,y0,0 in Z+ direction to check for mesh intersection to compute the support height h0

h0=center[2]+size[2]+1e6;

vector_ld(p,x0,y0,0.0);

vector_ld(dp,0.0,0.0,+1.0);

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

t=f->intersect_ray(p,dp);

if ((t>=0.0)&&(t<h0)) h0=t;

}

if (h0>center[2]+size[2]+1e5) continue; // skip non intersected rays

h0-=gap; if (h0<0.0) h0=0.0;

// main suport prism

ff.attr=attr0;

// sides

ff.attr=attr0;

vectorf_ld(ff.p[0],x0-hx,y0-hy,0.0);

vectorf_ld(ff.p[1],x0+hx,y0-hy,0.0);

vectorf_ld(ff.p[2],x0-hx,y0-hy, h0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0+hx,y0-hy,0.0);

vectorf_ld(ff.p[1],x0+hx,y0-hy, h0);

vectorf_ld(ff.p[2],x0-hx,y0-hy, h0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0-hx,y0-hy, h0);

vectorf_ld(ff.p[1],x0 ,y0+hy,0.0);

vectorf_ld(ff.p[2],x0-hx,y0-hy,0.0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0-hx,y0-hy, h0);

vectorf_ld(ff.p[1],x0 ,y0+hy, h0);

vectorf_ld(ff.p[2],x0 ,y0+hy,0.0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0 ,y0+hy, h0);

vectorf_ld(ff.p[1],x0+hx,y0-hy,0.0);

vectorf_ld(ff.p[2],x0 ,y0+hy,0.0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0 ,y0+hy, h0);

vectorf_ld(ff.p[1],x0+hx,y0-hy, h0);

vectorf_ld(ff.p[2],x0+hx,y0-hy,0.0); ff.compute(); fac.add(ff);

// base triangles

vectorf_ld(ff.p[0],x0 ,y0+hy,0.0);

vectorf_ld(ff.p[1],x0+hx,y0-hy,0.0);

vectorf_ld(ff.p[2],x0-hx,y0-hy,0.0); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x0-hx,y0-hy, h0);

vectorf_ld(ff.p[1],x0+hx,y0-hy, h0);

vectorf_ld(ff.p[2],x0 ,y0+hy, h0); ff.compute(); fac.add(ff);

// joints

for (x1=x0-(0.5*grid0),x2=x0-(0.5*grid2);x1<=x0+(0.5*grid0);x1+=grid1,x2+=ga)

for (y1=y0-(0.5*grid0),y2=y0-(1.9*grid2);y1<=y0+(0.5*grid0);y1+=grid1,y2+=ga)

{

// cast ray x1,y1,0 in Z+ direction to check for mesh intersection to compute the joint height h1

h1=h0+gap+1e6;

vector_ld(p,x1,y1,0.0);

vector_ld(dp,0.0,0.0,+1.0);

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

t=f->intersect_ray(p,dp);

if ((t>=0.0)&&(t<h1)) h1=t;

}

if (h1>h0+gap+1e5) continue; // skip non intersected rays

// tetrahedron joints

ff.attr=attr1;

// base triangle

vectorf_ld(ff.p[0],x2 ,y2+gy,h0);

vectorf_ld(ff.p[1],x2+gx,y2-gy,h0);

vectorf_ld(ff.p[2],x2-gx,y2-gy,h0); ff.compute(); fac.add(ff);

// sides

vectorf_ld(ff.p[0],x2+gx,y2-gy,h0);

vectorf_ld(ff.p[1],x2 ,y2+gy,h0);

vectorf_ld(ff.p[2],x1 ,y1 ,h1); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x2 ,y2+gy,h0);

vectorf_ld(ff.p[1],x2-gx,y2-gy,h0);

vectorf_ld(ff.p[2],x1 ,y1 ,h1); ff.compute(); fac.add(ff);

vectorf_ld(ff.p[0],x2+gx,y2+gy,h0);

vectorf_ld(ff.p[1],x2-gx,y2-gy,h0);

vectorf_ld(ff.p[2],x1 ,y1 ,h1); ff.compute(); fac.add(ff);

}

}

// reverse placement obj (may lose some accuracy) not needed if matrices are not used

for (f=fac.dat,i=0;i<fac.num;i++,f++)

{

for (j=0;j<3;j++)

{

for (k=0;k<3;k++) p[k]=f->p[j][k]; // float->double

obj.g2l(p,p);

for (k=0;k<3;k++) f->p[j][k]=p[k]; // double->float

}

for (k=0;k<3;k++) p[k]=f->n[k]; // float->double

obj.g2l_dir(p,p);

for (k=0;k<3;k++) f->n[k]=p[k]; // double->float

} compute();

}

//---------------------------------------------------------------------------

void STL3D::load(AnsiString name)

{

int adr,siz,hnd;

BYTE *dat;

AnsiString lin,s;

int i,j,l,n;

_fac f;

reset(); f.attr=0;

siz=0;

hnd=FileOpen(name,fmOpenRead);

if (hnd<0) return;

siz=FileSeek(hnd,0,2);

FileSeek(hnd,0,0);

dat=new BYTE[siz];

if (dat==NULL) { FileClose(hnd); return; }

FileRead(hnd,dat,siz);

FileClose(hnd);

adr=0; s=txt_load_str(dat,siz,adr,true);

// ASCII

if (s=="solid")

{

_progress_init(siz); int progress_cnt=0;

for (adr=0;adr<siz;)

{

progress_cnt++; if (progress_cnt>=128) { progress_cnt=0; _progress(adr); }

lin=txt_load_lin(dat,siz,adr,true);

for (i=1,l=lin.Length();i<=l;)

{

s=str_load_str(lin,i,true);

if (s=="solid") { name=str_load_str(lin,i,true); break; }

if (s=="endsolid") break;

if (s=="facet")

{

j=0;

s=str_load_str(lin,i,true);

f.n[0]=str2num(str_load_str(lin,i,true));

f.n[1]=str2num(str_load_str(lin,i,true));

f.n[2]=str2num(str_load_str(lin,i,true));

}

if (s=="vertex")

if (j<3)

{

f.p[j][0]=str2num(str_load_str(lin,i,true));

f.p[j][1]=str2num(str_load_str(lin,i,true));

f.p[j][2]=str2num(str_load_str(lin,i,true));

j++;

if (j==3) fac.add(f);

}

break;

}

}

}

// binary

else{

adr=80;

n=((DWORD*)(dat+adr))[0]; adr+=4;

fac.allocate(n); fac.num=0;

_progress_init(n); int progress_cnt=0;

for (i=0;i<n;i++)

{

if (adr+50>siz) break; // error

progress_cnt++; if (progress_cnt>=128) { progress_cnt=0; _progress(i); }

f.n[0]=((float*)(dat+adr))[0]; adr+=4;

f.n[1]=((float*)(dat+adr))[0]; adr+=4;

f.n[2]=((float*)(dat+adr))[0]; adr+=4;

for (j=0;j<3;j++)

{

f.p[j][0]=((float*)(dat+adr))[0]; adr+=4;

f.p[j][1]=((float*)(dat+adr))[0]; adr+=4;

f.p[j][2]=((float*)(dat+adr))[0]; adr+=4;

}

f.attr=((WORD*)(dat+adr))[0]; adr+=2; // attributes

fac.add(f);

}

}

_progress_done();

delete[] dat;

compute();

}

//---------------------------------------------------------------------------

void STL3D::save(AnsiString name)

{

// ToDo

}

//---------------------------------------------------------------------------

void _progress_init(int n)

{

#ifdef ComctrlsHPP

if (progress==NULL) return;

progress->Position=0;

progress->Max=n;

progress->Visible=true;

#endif

}

//---------------------------------------------------------------------------

void _progress (int ix)

{

#ifdef ComctrlsHPP

if (progress==NULL) return;

progress->Position=ix;

progress->Update();

#endif

}

//---------------------------------------------------------------------------

void _progress_done()

{

#ifdef ComctrlsHPP

if (progress==NULL) return;

progress->Visible=false;

#endif

}

//---------------------------------------------------------------------------

#endif

//---------------------------------------------------------------------------

Usage is simple:

#include "STL3D.h" // STL mesh (this is the important stuff)

STL3D mesh; // point cloud and tetrahedronal mesh

mesh.load("space_invader_magnet.stl");

mesh.supports(obj); // obj is object holding 4x4 uniform matrix of placement if you STL is already placed than it is not needed

I used a lot of stuff from mine OpenGL engine like dynamic List<> template:

List<double> xxx; is the same as double xxx[];

xxx.add(5); adds 5 to end of the list

xxx[7] access array element (safe)

xxx.dat[7] access array element (unsafe but fast direct access)

xxx.num is the actual used size of the array

xxx.reset() clears the array and set xxx.num=0

xxx.allocate(100) preallocate space for 100 items

or vector and matrix math (vectorf_ works with float* and vector_ with double) which is not too important. If you need the math see:

If the STL is already placed (no matrix) than no placement conversions nor the obj is needed at all. The code reflects the bullets above. I wanted to keep it as simple as I could so no optimizations are there yet.

The gap and grid constants are hard-coded in the supports function and are not yet set to the valid values.

[Notes]

Now this barely cover only the very basic of the problem and there are a lot of edge cases left un-handled to keep this "short". The code itself does not check if triangles are above the 45 degree slope but that can be done with simple normal angle checking like:

if (acos(dot(normal,(0.0,0.0,1.0))<45.0*deg) continue;

There is the need to add also the supports between parts of mesh for example if your object has more layers than only the first layer will be supported from base plane. the rest must use the layer below itself ... and using weakened joint on both sides of support. That is similar to place the first layer of supports you just need to cast the ray in both directions ... or cast continuous ray going through the whole bbox and check for start/end surfaces by analyzing normal direction to ray (simple sign of dot product). For example this is mesh placement that would possibly need this (for some technologies):

While designing the supports take in mind you should meet the proper winding rule (CCW) and normal direction (out) for the printing process ...